|

ETA Heiztechnik PE 7 / 11 PelletsUnit The new PE 7 / 11 wood pellet boiler from ETA Heiztechnik in Austria comes to the Irish market with many new innovative features that make this boiler stand head and shoulders above the rest. Although the boiler may be small on size it is by no means small on features, in fact the boiler has so much packed into such little space it has been winning awards all over Europe with the most notable award being the “ENERGY GENIE” award at the international renewable energy exhibition in Wels during 2008.

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

DESIGN A major problem with most biomass boilers is trying to find space for boiler, fuel store plus a range of manifolds and pumps. ETA have taken a concept that has been embraced by Natural Gas boiler manufacturers and used to make the PE 7 / 11 the first biomass central heating boiler to offer the following items;

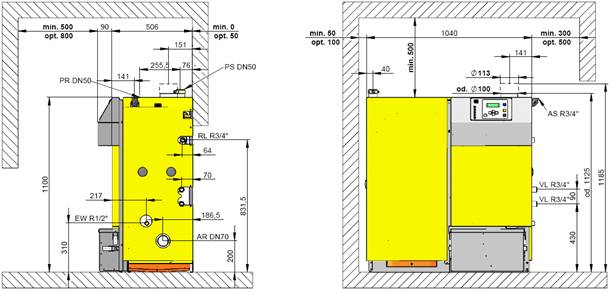

The PelletsUnit has been designed with passive houses and modern conventional houses in mind. The 7kW boiler is ideal for use as a backup boiler in passive houses, whereas the 11kW version can heat a house up to 250m2 in size that has been built to today’s building regulations. Designers have specifically kept in mind the need to fit the PelletsUnit into today’s buildings and apartments, coming in with a footprint of 696mm x 1040mm the PE 7 / 11 is the smallest, fully automatic, biomass boiler on the market. The design is such that the boiler can be pushed right in against the wall on two sides to make sure that there is no dead space. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

CONVENIENCE The system is fully automatic and requires minimum maintenance by the customer and all of the following features are fitted as standard

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

EFFICIENCY The new PE 7/11 boiler also weighs in as being one of the most efficient boilers on the market for converting combustible fuel energy into usable heat energy for the home. If the PelletsUnit is installed inside the house then the boiler is able to extract 97.5% of useable heat from burning wood pellets, losing just 2.5% of the heat up the chimney. Compare this to other house heating systems.

The PelletsUnit is able to achieve such high levels of efficiency as a result of a highly efficient burning grate that is able to remove ash from the burning are almost as soon as it is formed. This gives rise to longer and better burning of the wood fuel in the grate and as a result leaves very little ash residue – the customer will have to empty the ash bin on average 2 times per year.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

WEATHER INFLUENCED HEATING If the customer utilizes the boiler controls to their full potential then they can live in a house with weather influenced heating. What’s that you may ask? To put it simply it is a system that allows the boiler to automatically increase/decrease the water flow temperature depending on the outdoor temperature. How does this work? There are two parts to this equation that the PelletsUnit uses when deciding what temperature to send water to the radiators at – 1.) Outdoor temperature, and 2.) Indoor temperature. Outdoor Heating Curve The boiler uses a sliding scale for setting a base temperature for heating the water to, for example if the outdoor temperature at -10°C means 60°C water and outdoor temperature at +10° means 35° water. Using an outdoor temperature probe the boiler will automatically choose the base temperature for the water flow temperature, so at 0°C outdoor temperature the boiler would send water at 47°C to the radiators. Indoor Heating Boost Using its own room thermostat the boiler constantly monitors the indoor temperature of the house and adds a boost to the water flow temperature for every degree the room is below the desired room temperature. If we continue on from the above paragraph we can calculate the water flow temperature that the boiler will send to the radiators.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

So as the room temperature gets closer to its target the lower the water temp flow to the radiator gets. By utilizing this system the room temperature will always be comfortable with a lot of radiant heat keeping the room at that level and less of the hot / cold scenario that is common when using standard boiler setups. In addition, if the outdoor temperature rises above a pre-set level, the PelletsUnit will decide that the weather is too good to have central heating switched on and will only heat the hot water cylinder. If the temperature drops down below this level then the PelletsUnit monitors room temperature again.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

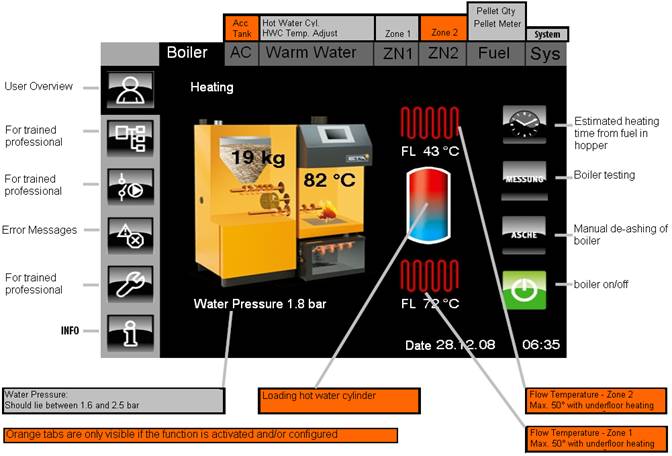

USER INTERFACE The user interface on the PE 7/11 boiler is also a first in class with a built in touch screen LCD panel. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The panel offers clear and concise data for the customer to view when required and changing values is as easy as tapping a few areas on the screen. The built in memory of the UI means there is no longer a need for a paper operating manual because the user manual is built into the unit and can be accessed by pressing the info button. CONTROL The boiler has quite a number of other features built into the control panel including controls for both buffer tank management and solar panel management. If the boiler is installed without a buffer tank then solar panels can be managed by the PelletsUnit to heat a twin coil solar tank. The boiler will give priority to the solar panels based on the time of day, temperature of solar panels and temperature of solar tank. The boiler will only heat up the solar tank when it is happy that there is not enough solar energy available to do so. Likewise, if the customer installs a buffer tank with a solar coil the PelletsUnit will give the same priority to solar heating before it kicks in to heat the buffer tank. This type of setup gives the customer the option of using solar heat in the heating system as well as the hot water cylinder. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||